Keep your teams and equipment safe with our electric tug maintenance guide.

Whether it’s a Mini, Maxi or Major MotorMover, every electric tug requires regular maintenance to withstand the pressures of loading.

More importantly, electric tug maintenance guarantees user safety. Neglect can lead to preventable technical issues developing, which may pose a safety risk.

To stay on top of your electric tug maintenance, follow these tips on inspection and servicing.

Maintenance versus servicing: understanding the difference

While both maintenance and servicing are integral to machine life and user safety, there is a key difference in implementation.

Maintenance can be carried out by the machine operator and should take place daily, with more thorough weekly checks. As outlined in UK Health and Safety guidelines, all equipment which may pose a risk to the user should undergo these regular checks.

Daily checks

Daily check training will be covered in any installation training or re-training. Operators should judge inspections on a case-by-case basis, relative to how often the machine is used and any wear and tear.

These checks include:

- Ignition key, switch and horn testing

- Operational checks on the lift and lower mechanism, direction levers and the anti-pinch safety function

- Visual inspection of external battery leads, hoses and battery charge

- Oil leaks (if the machine has been stationary for a while)

- Damage to metal work and operating elements

- Smooth running without ‘creeping’, and controlled stopping.

Weekly checks

These more thorough checks involve all of the above, plus:

- Visual inspection of metal work weld fractures or breakage, and loose bolts/fasteners

- Visual charger inspection, disconnected from the mains

- Battery water levels

- Cleaning with damp cloths for dusty environments.

Servicing

A more thorough MotorMover service will likely not be carried out by the operator, but by a third-party professional. At MotorMover, we carry out all our services on-site to minimise disruption.

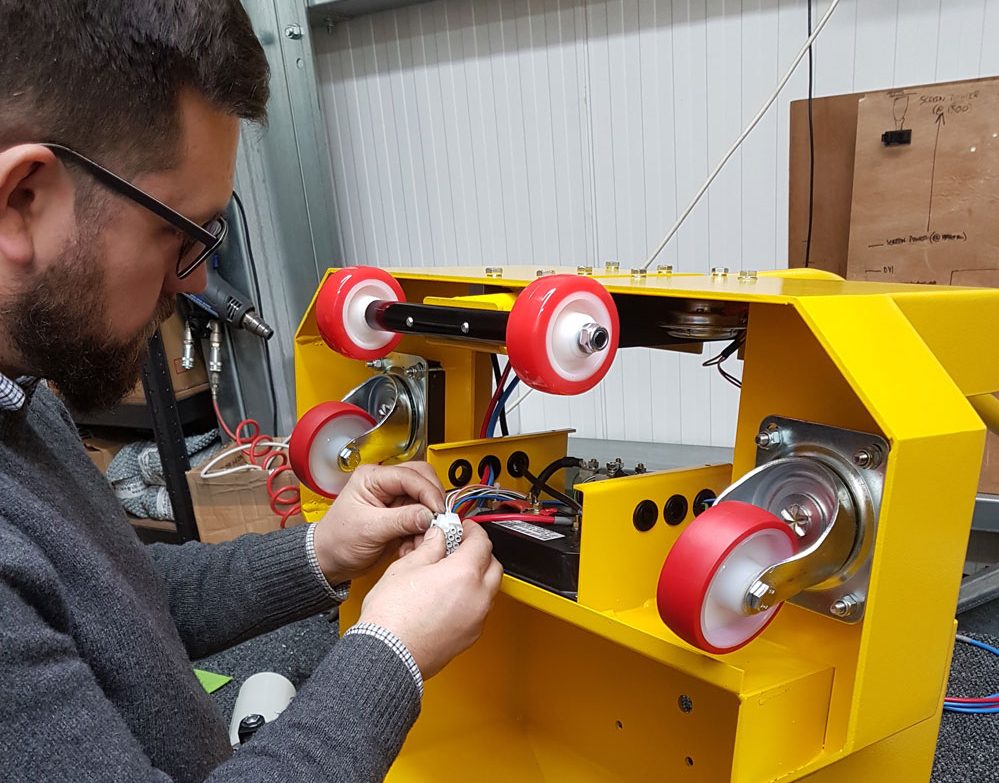

Servicing involves disassembling the machine to identify any potential issues. Operators should book in a service at least once per year, depending on how often the machine is used and the weight it bears.

A full electric tug maintenance service includes:

- A thorough strip and inspection of all major components

- Repairs to components (with all major parts available in a stocked service van)

- Chassis and couplings inspected for damage

- Fasteners retorqued

- A full functional test

- Trailers and loaders inspected optionally, as agreed in the service package.

Why do I need electric tug maintenance?

As operators, you are legally obliged to keep your staff safe. Maintenance complies with the Provision and Use of Work Equipment Regulations Act (1998), which states that inspections must take place at “regular intervals”.

Maintenance prolongs your MotorMover’s life, helping to reduce costs and avoid any costly legal issues through damage or injury claims.

With MotorMover, you can customise your service package to suit any existing machines you own. We offer standard and premium packages for up to five years, including parts and labour discounts, and emergency callouts.

For more information, book your service with MotorMover here.